Broad collaboration around batteries for Sweden’s green transition

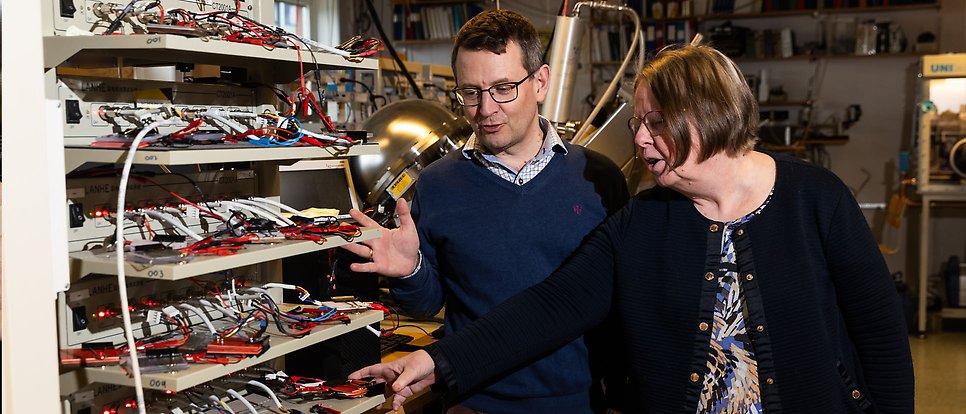

Daniel Brandell is the coordinator and Kristina Edström the director of the national competence centre Batteries Sweden (BASE). Photo: Bildbyrån

The researchers at Batteries Sweden (BASE), the national competence centre in this area, are working on the development of new types of lightweight, inexpensive, environment-friendly and safe batteries with ultra-high energy storage capacity. BASE aims to promote cooperation between Swedish industry partners and academic partners in different sectors of the battery value chain.

“This centre is essential to coordinate and strengthen the entire area,” says Daniel Brandell, Professor of Materials Chemistry at Uppsala University and Coordinator at BASE.

BASE started its operations in spring 2020 under the directorship of Kristina Edström, Professor of Inorganic Chemistry at Uppsala University. It’s the latest in a number of important roles for this battery researcher, who also coordinates the EU initiative Battery 2030+ and the battery platform COMPEL (COMPetitiveness for the ELectrification of the transport system).

BASE has 18 industry partners including ABB, Volvo, Scania and Northvolt, as well as four academic partners: Uppsala University, Chalmers University of Technology, KTH Royal Institute of Technology, and RISE Research Institutes of Sweden.

The goal: concrete products

“The battery value chain involves mining, materials, battery production, battery use and finally recycling. Long term, we hope that the collaboration projects within BASE will lead to concrete products,” says Daniel Brandell.

To date, 19 collaboration projects have been started. These projects are conducting research that it is hoped will lead to the development of new materials – primarily for anodes, cathodes and electrolytes, but also for sensors and new methods for analysing and modelling batteries. All of these types of projects are needed to create sustainable, durable batteries that can store a lot of energy.

“In addition, while the reactions within the materials must be kept stable, the batteries must also be able to charge quickly. This is a challenge”.

Inexpensive and sustainable materials

A project involving a collaboration between Uppsala University and the companies Altris and ABB is focussing on new electrolytes for safer batteries.

“In 2023, electrolytes for sodium-ion batteries were investigated, for example. Sodium-ion batteries contain materials that are both cheaper and more environmentally sustainable than those we have in our electric cars today,” says Daniel Brandell.

“And we’re also working on new recycling techniques for batteries to increase recycling efficiency. We need efficient recycling too if we are going to create a circular economy.”

Skills that are in high demand

According to Daniel Brandell, the battery field is moving extraordinarily fast, which is extremely important for the green transition in Sweden and worldwide.

“Sweden is well-positioned in this area. We’re a major producer of lithium-ion batteries, which in fact will be able to contribute to the green transition and help transform Sweden’s industrial landscape.

But there is also an acute shortage of skills in the battery area in Sweden. That’s another sphere where BASE can contribute its expertise and know-how to assist in the transition, he says.

“BASE is an excellent actor for connecting industry and academia. The contacts we acquire and the networks we maintain through the competence centre lay the foundations for successful grant applications, which in turn enable us to bring more resources into this important field of research. And with BASE, we’ve successfully formed a hub that brings together all the actors in Sweden’s battery industry so that we all feel we’re doing things together for the industry as a whole.”

Anneli Björkman

Batteries Sweden (BASE)

- The Batteries Sweden (BASE) competence centre at Uppsala University is being funded equally during 2020 – 2025 by Vinnova, the participating higher education institutions, and the participating companies – one third each. The total budget is approximately SEK 100 million.

- BASE brings together 4 academic partners and 18 industry partners: Uppsala University, Chalmers University of Technology, KTH Royal Institute of Technology, RISE, ABB, AB Volvo, SAFT, Scania, Volvo Cars, Stena Metall, Northvolt, Altris, COMSOL, Graphmatech, Gränges, Insplorion, Percyroc, Quintus Technologies, Talga, Woxna AB/Leading Edge Materials, Excillum and NOVO.

- Vinnova recently gave BASE good marks in an evaluation, which means that the centre can now apply for an extension.