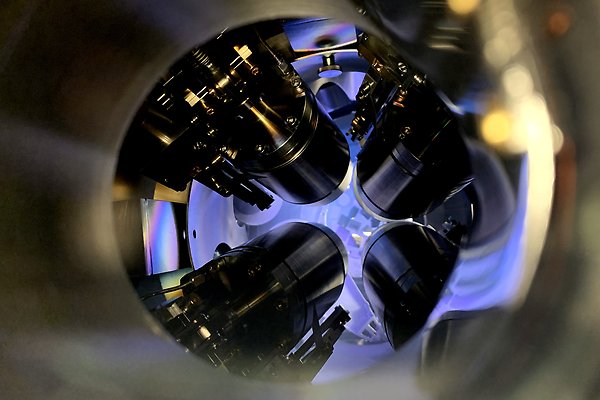

Magnetron sputtering system

In addition to materials characterisation and modification, we also have the possibility to directly fabricate thin films at the Tandem laboratory. We have a customised Prevac magnetron sputtering set-up available allowing us to deposit films and coatings of various materials. Previous projects include the successful sputter-deposition of EUROFER97 and high-purity tungsten films for fusion applications, the growth of vanadium films for studies on hydrogen storage as well as the fabrication of photochromic films.

Part of Nuclear Materials and Energy, 2023

- DOI for Thin films sputter-deposited from EUROFER97 in argon and deuterium atmosphere: Material properties and deuterium retention

- Download full text (pdf) of Thin films sputter-deposited from EUROFER97 in argon and deuterium atmosphere: Material properties and deuterium retention

Features

- 4 magnetrons, all usable at the same time allowing co-deposition of up to 4 different materials.

- 2 of the magnetrons operated in DC and 2 in RF mode; the latter permitting the deposition even from insulating sputter targets.

- Gas inlet featuring 3 mass flow controllers enabling reactive sputtering with one gas or a mixture of gases.

- Maximum substrate size: ∅ 50.8 mm (2'').

- Rotatable sample stage to ensure uniformity of the produced films.

- Heating stages in the load-lock and main chamber allowing for in-situ annealing.

- In-situ monitoring of deposition rates possible with a quartz crystal microbalance (QCM) installed inside the sputtering chamber.

- Base pressure in the sputtering chamber: < 10-7 mbar.