Low-energy systems

Time-of-flight low-energy ion

scattering system

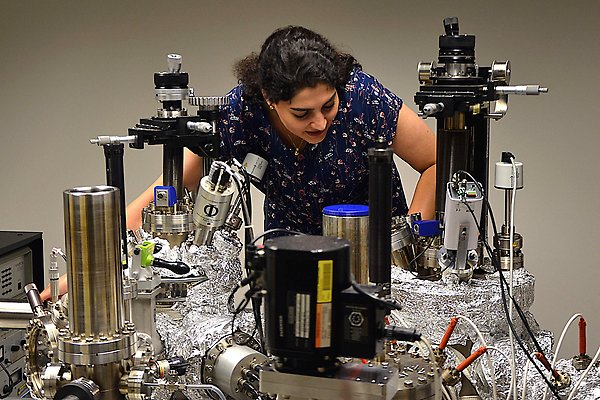

Our time-of-flight low-energy ion scattering (ToF-LEIS) system was transferred from the Johannes Kepler University Linz, Austria to the Tandem laboratory in 2018. ToF-LEIS is an analytical surface science technique using comparably slow ions. These ions, produced from gases such as helium or neon, have energies below 10 keV and therefore do not penetrate deep into the bulk but scatter from the first few atomic layers of a sample. Analysis of the chemical composition of the near-surface region of a sample with a depth resolution of down to 1 Å is hereby possible.

The ToF-LEIS beam line is complemented by a sample preparation and analysis chamber making it possible to fabricate, clean and analyse surfaces within one UHV system. This set-up is therefore ideal for studying surface and near-surface effects such as diffusion, adsorption, and contaminations. Recent ToF-LEIS studies conducted in our laboratory include the formation of different crystalline structure of ultrathin nickel silicide films relevant for contact layers in modern electronics. Another example is the surface segregation and diffusion of components of EUROFER97 steel planned to be used in future fusion devices.

Part of Nuclear Materials and Energy, 2022

- DOI for An in-situ ToF-LEIS and AES study of near-surface modifications of the composition of EUROFER97 induced by thermal annealing

- Download full text (pdf) of An in-situ ToF-LEIS and AES study of near-surface modifications of the composition of EUROFER97 induced by thermal annealing

Part of Small, 2022

- DOI for Direct Transition from Ultrathin Orthorhombic Dinickel Silicides to Epitaxial Nickel Disilicide Revealed by In Situ Synthesis and Analysis

- Download full text (pdf) of Direct Transition from Ultrathin Orthorhombic Dinickel Silicides to Epitaxial Nickel Disilicide Revealed by In Situ Synthesis and Analysis

Features ToF-LEIS system

- Gas ion source allowing for easy switching between different gases. Commonly employed ion beams include H, He and Ne.

- Ion energies between 0.5 and 10 keV.

- Electrostatic chopping of the ion beam proving the basis for time-of-flight measurements.

- Detection of backscattered particles under a scattering angle of 129°.

- Separation of charged from neutral scattered particles possible allowing to access information from different layers of the sample.

- Annealing of the sample at up 900°C.

- Base pressure: 2 x 10-10 mbar.

Features sample preparation chamber

- 3-cell evaporator (Omicron model EFM 3T) allowing for in-situ sample growth of up to 3 materials simultaneously.

- Sputter gun with ion energies of 5 keV and currents of a few nA.

- Annealing of the sample at up to 1000°C.

- Auger electron spectroscopy set-up (PHI model 10-155).

- Low-energy electron diffraction set-up (ErLEED 3000 SPECS GmbH).

- Ultrahigh vacuum with base pressure of 4 x 10-10 mbar.

- Gas exposure of the sample possible.