Additive manufacturing

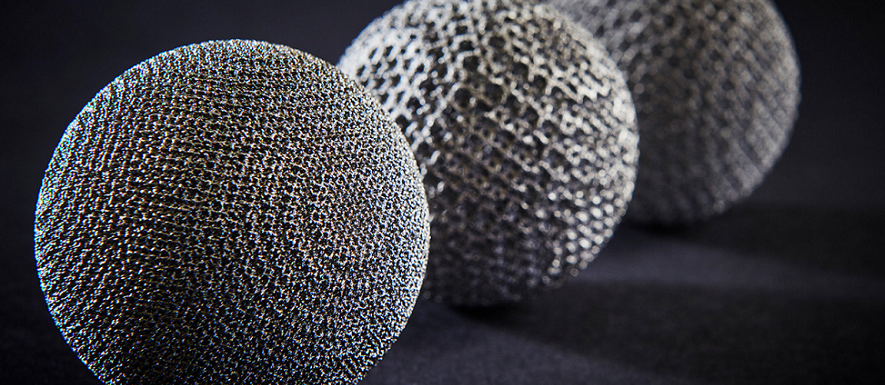

Additive manufacturing (AM) or 3D printing makes it possible to build from metallic glasses, metastable materials and alloys with unique microstructures.

Our research

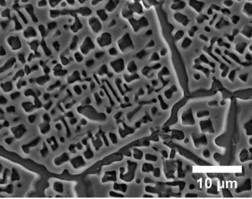

Additive manufacturing (AM) or 3D-printing is a rapidly growing area in modern industry. From a materials chemistry point of view it opens up completely new research fields. Many AM processes such as laser-based powder bed fusion occur under extreme conditions with, for example, cooling rates > 105 K/s. This means that solidification, phase transformations and other chemical reactions can be different from conventional processes. This makes it possible to build, for example, large samples of metallic glasses, metastable materials and alloys with unique microstructures.

We are actively working in a wide range of projects including, the development of new AM alloys, textured materials and in the surface modification of powder used in AM.

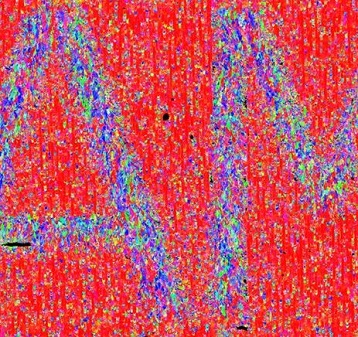

Design of anisotropic properties with AM

Most metals are polycrystalline, i.e. consist of aggregate of many crystals, with many of their properties determined by the average orientation of these crystals (known as texture or preferential orientation). Additive manufacturing can be used to influence this preferential orientation and enhance material properties. Mechanical properties and the performance of permanent magnets are examples of properties that can be improved with a microstructure that exhibits a strong preferential orientation.

Contact: Prof. Martin Sahlberg

Materials development for AM

Future AM processes need new alloys. Today only a few conventional alloys are used in AM. We are working on the design of new alloys such as high entropy materials, amorphous materials, composites, new steel grades and other previously not studied AM materials. We are combining thermodynamic modelling, process development and materials analysis and characterization to identify and develop new AM materials. Many of our projects are carried out with industrial partners.

Contact: Prof. Ulf Jansson and Prof. Martin Sahlberg

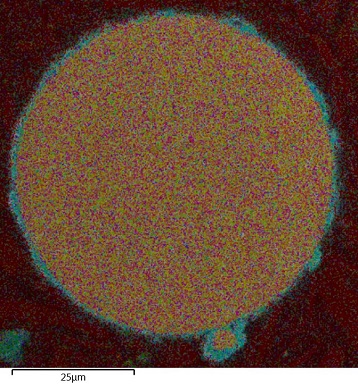

Modification of powders for AM

Most additive manufacturing processes use metal powders as starting material, which makes the powder essential for both the printing process, but also for the formed material. Modifying the existing metal powders opens up many possibiliites: Both to control and modify the powder properties to suit the AM process at hand; and to create new materials or microstructures in the printed materials. Within the inorganic research programme we currently pursue several projects connected to powder modification for AM, mainly together with industrial partners, including Sandvik additive and Graphmatech

Contact: Prof. Ulf Jansson and Ass. Prof. Erik Lewin

Contact

- If you have questions about our research, you are welcome to contact the programme professor Professor Martin Sahlberg.

- Martin Sahlberg