New materials for harsh environments

We are researching materials that can withstand corrosion, abrasion and can be used in the nuclear energy field.

Our research

Many materials are used in tough and harsh environments. There is need for new materials which can withstand very corrosive environments or high temperatures without oxidation or detrimental phase transformations. In many applications materials are exposed to high loads, stresses, erosion, radiation etc which can destroy or seriously damage the material. There is also a need for new materials which exhibit functional properties also at harsh conditions. This includes, for example, sensor materials and catalysts.

Corrosion Resistant Materials

Despite decades of research, corrosion remains a very important omnipresent problem as corrosion leads to the degradation of a material due to reactions with its environment and causes numerous problems. This research field deals with fundamental electrochemistry and the development of multicomponent corrosion resistant thin films with high entropy alloy (HEAs) compositions, which show high corrosion resistances even in harsh environments.

Hard and abrasion resistant materials

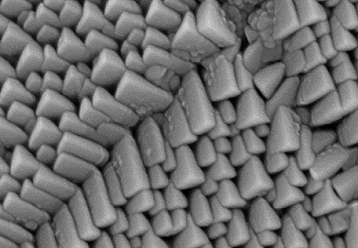

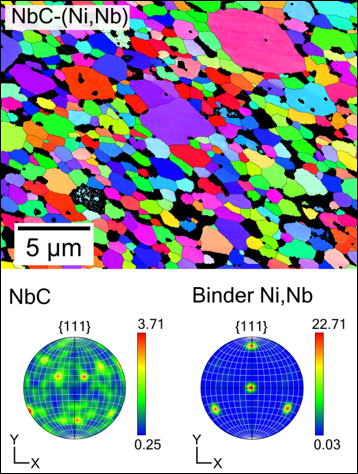

We have a large activity on thin film synthesis on hard and abrasion resistant coatings using both solution chemistry and vapour deposition methods such as chemical vapour deposition (CVD) and magnetron sputtering. A major aim with the research is to control the phase composition and microstructure of our materials and establish the correlation between microstructure and properties. We are currently studying a wide range of new types materials such as borides, carbides, nitrides and oxides for different applications.

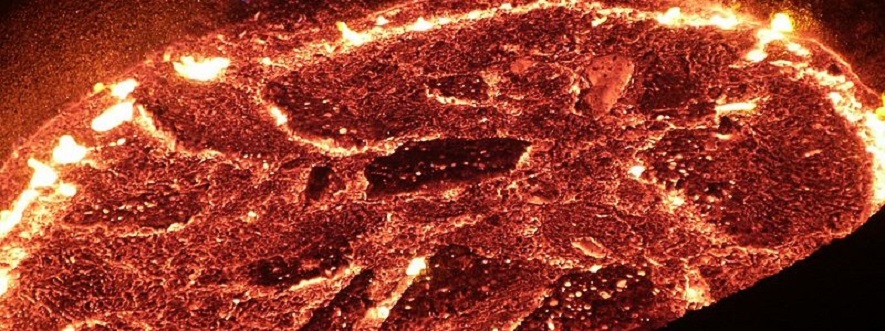

Materials for nuclear power applications

Within the SSF ARC Sunrise six-year project, aiming at verifying a Gen IV lead cooled reactor design and materials for the construction of a test reactor, materials are developed and tested for their performance in various parts of the reactor. This kind of reactors work at 500OC+ and must sustain their integrity over long times in the hot molten lead. Depending on the place and function of the material there are different requirements. Our focus is on (i) materials for the impellers, which must be resistant to erosion (ii) coatings on steel to enhance the naturally formed surface structure and composition and (iii) synthesis of (Zr/U)N nano-powders for sintering into fuel pellets. This also includes various, e.g. Lanthanide dopants to simulate fission products formed during operation.

Contact

- If you have questions about our research, you are welcome to contact the programme professor Professor Martin Sahlberg.

- Martin Sahlberg