Neutron imaging of LBPF

Neutron imaging reveals texture variations and hidden nucleation sites for failure in laser powder-bed fusion

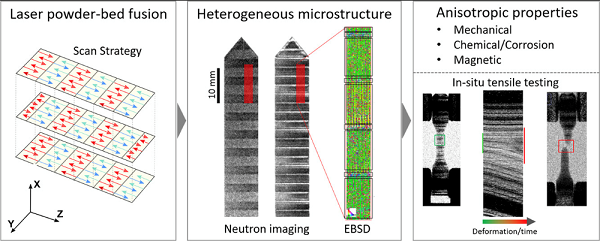

Laser powder-bed fusion (LPBF) is one of the most widely used Metal additive manufacturing (AM) technique, often referred to as 3D printing. In LPBF, a laser is used to selectively melt areas of a thin powder layer (powder-bed) according to a digital model. New layers are subsequently added and the process is repeated until the object is completed.

AM techniques are not only expanding our capabilities to design components with complex shapes, but also open new pathways for the creation of materials with tailored microstructures and hence mechanical as well as functional properties. The successful manufacturing of components by LPBF requires careful selection of process parameters (such as laser power, layer thickness, etc.) and scan strategies (laser beam movement). It has been known that the scan strategy can influence the microstructure and texture (i.e. the preferred orientation of the crystal grains within the material). Past studies have however largely overlooked that different scan strategies can inadvertently produce local microstructure alterations and preferential grain orientation over small areas – which can likely be attributed to a lack of suitable experimental techniques that work across cm-sized parts.

The current work reveals and explains this effect in parts made from 316L stainless steel, using a combination of neutron imaging, neutron diffraction and electron backscatter diffraction. During an in-situ tensile test, neutron imaging shows that – what seem to be minor changes in the scan strategy, can have significant effects on the mechanical performance and reveals locations where failure begins. The researchers also highlight that their manuscript can serve as an ideal reference for the – yet challenging – interpretation of neutron ‘Bragg edge imaging data’ in general, by showing the relationship between measured and simulated data, pole figures and EBSD in an unprecedented level of detail, e.g. benefitting future users of the future ODIN and BEER instruments at ESS.

Publication

- Pacheco, V., Marattukalam, J. J., Karlsson, D., Dessieux, L., Van Tran, K., Beran, P., Manke, I., Kardjilov, N., Markötter, H., Sahlberg, M. & Woracek, R. On the relationship between laser scan strategy, texture variations and hidden nucleation sites for failure in laser powder-bed fusion. Materialia 26, 101614, https://doi.org/10.1016/j.mtla.2022.101614 (2022).

Contakt: Martin Sahlberg

Contact

- If you have questions about our research, you are welcome to contact the programme professor Professor Martin Sahlberg.

- Martin Sahlberg